Master Class of Spinning

In the very heart of Lapuan Kankurit, there is the desire to maintain and develop traditional weaving skills and culture and bring them to modern times. In 2022, our own wool spinning mill and finishing facility will be completed and we’ll be able to have practical use of the local sheep’s wool. We are assisted by experienced masters, like Rainer Koivula, who has been working with textiles for almost 50 years. In autumn 2021, Rainer Koivula transferred the wool spinning machines from the former Suupohjan Kehruutehdas spinning facility to the new wool spinning mill of Lapuan Kankurit. This may sound like a simple project, but there is much more to it. The wool carding and the spinning machine are both over 20 metres in length and tons in weight. Rainer has pulled down the equipment piece by piece. Then the pieces have been loaded in a truck and moved 100km distance to Lapua.

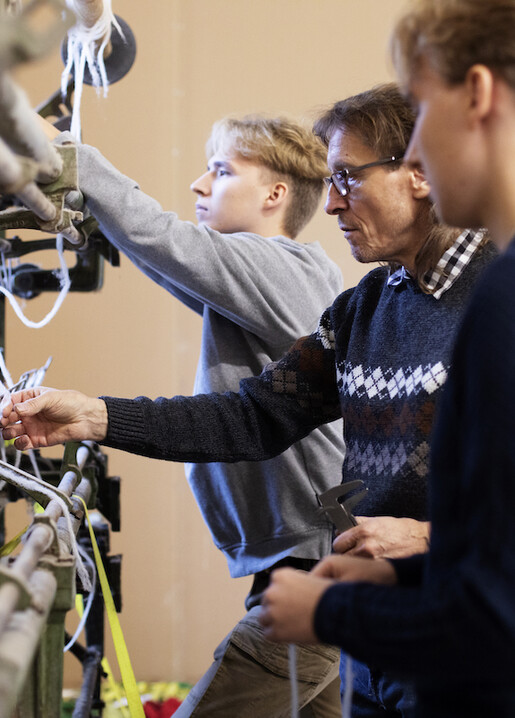

In Lapua, the 19-year-old twins Eero and Elias Hjelt who’s family entrepreneuship Lapuan Kankurit is, have cleaned the machine parts alongside their studies, and have also learned a lot, when Rainer Koivula has reassembled the machines back to working condition. “The work is physically hard and challenging, as the entity is so large. But the meaningfulness of the work beats the stressfulness, because it is such a positive thing that an initiative like this exists”, says Rainer. Now that Lapuan Kankurit starts to manufacture wool yarn of local sheep’s wool, we will have more of the textile industry back in Finland, where it had already disappeared. Here, we have the opportunity to make good use of the Finnsheep’s wool that would otherwise partly go to waste. “The project has been demanding. It has involved building two manufacturing facilities, procurement of new equipment and modernising of old. As well as gathering responsible wool from local farms, experiments with plant dyeing and taking the circular economy and then ecological aspects into account in every step of the way. The project wouldn’t work out without the knowhow of Rainer Koivula. It is something many of us don’t have anymore.

Rainer started working in in the textile industry when he was under twenty years old, working for a loom tackler in Vaasa cotton factory. After that, he has had a decades’ career in weaving mills, as a machine technician and as a weaving mill entrepreneur. “It feels good that the old method is renewed. While we deal with traditional method, we can do things in a new way”, says Rainer. Rainer’s colleagues appreciate especially his attitude. When technical problems or other issues come in his way, Rainer amiably states: “Things always have a way of working themselves out.” The new wool spinning mill and finishing facility of Lapuan Kankurit will be completed during the year 2022. In 2022-2023, the first products weaved with Finnsheep’s wool yarn will be ready to be introduced to our customers. The products are a combination of traditional wool knowhow and modern design. “I have hoped that an era like this would come. That the local sheep’s wool would be highlighted. It will become again a tangible part of people’s everyday life, close to us people”, Rainer says.

Text Tia Nikkinen photos Katja Lösönen

Read more: Way of Living SS2022